Have you ever found yourself frustrated with your vehicle’s engine performance? If your car seems to lack power or struggles with efficiency, the issue might be compression in the cylinders.

When cylinder compression falters, it can lead to a host of problems, affecting the heart of your vehicle’s operation. But don’t worry, you can tackle this issue effectively with the right know-how and tools. Imagine driving with the full power of your engine, feeling confident every time you hit the road.

Fixing compression problems in your cylinders can restore that power, and it’s easier than you might think. This guide is designed to empower you with practical steps and insights to get your engine back to peak performance. Keep reading, and you’ll discover simple yet effective solutions that could transform your driving experience.

Signs Of Compression Issues

Difficulty starting the engine might signal compression problems in cylinders. Reduced power and poor fuel efficiency are common indicators. Addressing these issues promptly can restore engine performance and prevent further damage.

Understanding the signs of compression issues in your vehicle’s cylinders is crucial for maintaining engine health. Identifying these signs early can save you from costly repairs and lengthy downtime. So, what should you be looking for in your car’s performance?Reduced Engine Power

When your car struggles to accelerate, it might be more than just an old spark plug. Compression issues often lead to reduced engine power, causing your vehicle to feel sluggish. Imagine trying to sprint with a sprained ankle; your engine is facing a similar challenge. Next time you’re merging onto the highway, pay attention to your car’s response. Does it lack the usual pep? This could be a sign that your cylinders aren’t compressing as they should.Excessive Oil Consumption

Is your car guzzling oil like there’s no tomorrow? Excessive oil consumption could indicate a compression problem. When cylinders wear out, they can allow oil to seep into combustion chambers. You might find yourself topping off oil more frequently, a clear red flag. Have you noticed blue smoke from the exhaust? That’s another telltale sign. Keep track of your oil changes and consumption to catch this issue early.Misfiring Or Rough Idling

Ever felt like your car is having its own dance party at a red light? Misfiring or rough idling can be more than just a nuisance. Compression issues often cause the engine to misfire, creating an uneven, shaky experience. It’s like trying to maintain a steady beat on a broken drum. Listen closely to your engine while idling. Does it purr smoothly, or does it sound like it’s coughing? This symptom is not just annoying; it’s a signal your engine needs attention. Have you experienced any of these signs in your car? Don’t ignore them. Addressing compression issues promptly can prevent further damage and keep your vehicle running smoothly.

Credit: m.youtube.com

Diagnosing Cylinder Compression Problems

Fixing cylinder compression issues involves checking for leaks and inspecting the piston rings. Compression testing helps identify the problem areas. Replacing worn components restores the engine’s efficiency, ensuring optimal performance.

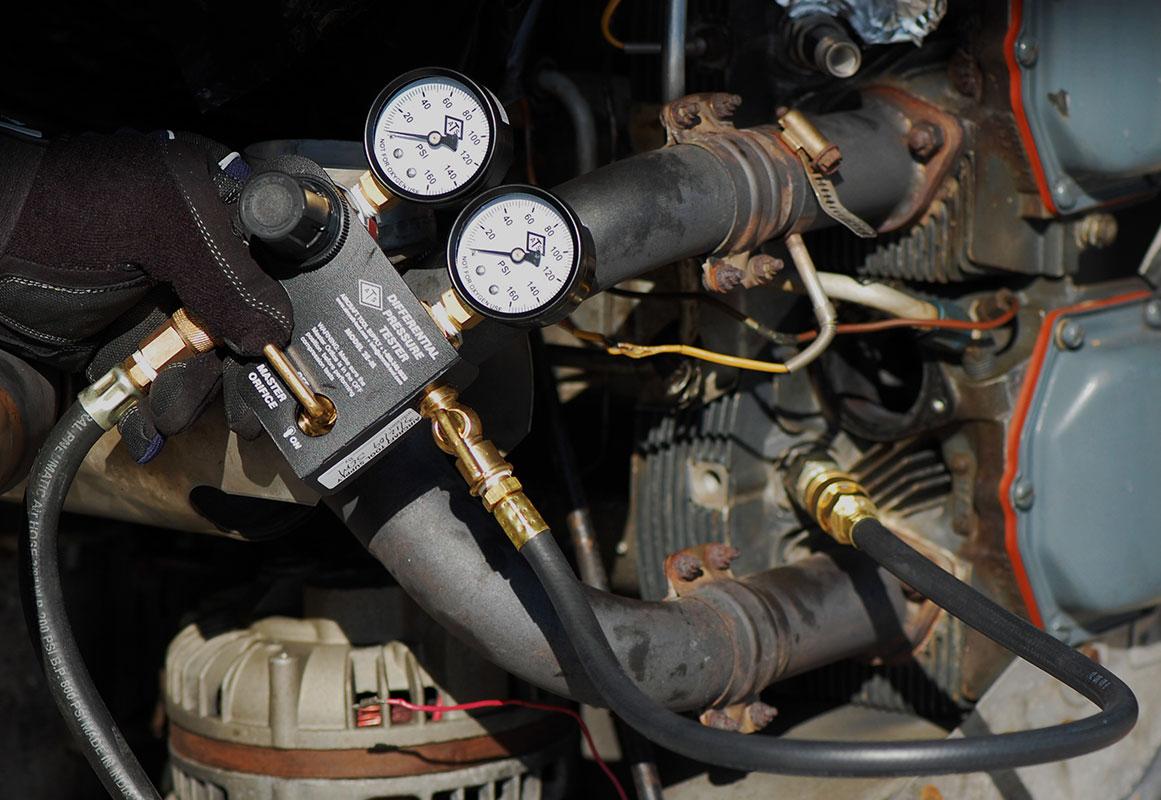

Diagnosing cylinder compression problems can be a crucial step in maintaining the health of your engine. Compression issues often manifest as poor engine performance, increased fuel consumption, or even difficulty in starting the vehicle. Understanding how to diagnose these issues can save you time and money, and extend the life of your car. ###Conducting A Compression Test

To diagnose compression problems, start by conducting a compression test. This test measures the pressure produced by each cylinder in the engine. You’ll need a compression gauge and a few basic tools. Begin with a warm engine. Remove the spark plug from the first cylinder. Insert the compression gauge into the spark plug hole. Turn the ignition key and crank the engine for a few seconds. Take note of the reading on the gauge. Repeat this process for each cylinder. ###Interpreting Test Results

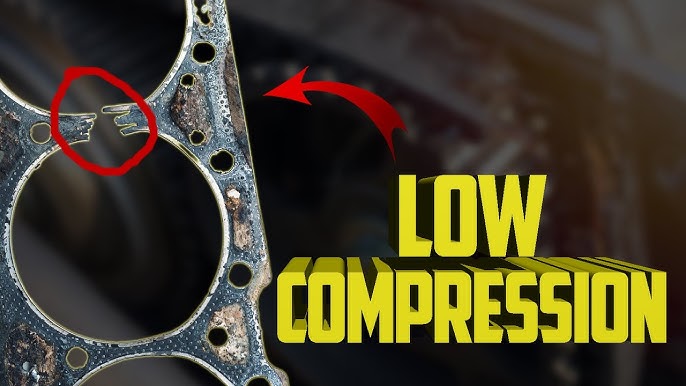

Now that you have your readings, what do they mean? Ideally, all cylinders should have similar compression readings. Variations can indicate issues. A healthy engine usually shows compression readings between 120 and 200 psi. If one cylinder is significantly lower than the others, it could point to a problem. Consistently low readings across all cylinders may suggest a larger issue, like a worn-out engine. ###Common Causes Of Low Compression

What might cause these variations in compression? Several issues could be at play. Worn piston rings can allow air to escape, reducing compression. Damaged valves can prevent the cylinder from sealing properly, leading to compression loss. A blown head gasket often causes compression to leak between cylinders or into the cooling system. Have you ever noticed a drop in your car’s performance? It could be time to investigate the compression. Regular maintenance and early diagnosis can prevent more significant engine problems down the road. By understanding the root causes and fixing them promptly, you ensure a smoother ride and better fuel efficiency.Repairing Cylinder Compression

Repairing cylinder compression is vital for engine performance. Low compression affects efficiency and power. Fixing this issue enhances fuel economy and engine life. Addressing compression problems involves several steps. Understanding each part helps in effective repair.

Replacing Worn Pistons And Rings

Worn pistons and rings cause low compression. Check for wear and tear. Replace damaged parts with new ones. Ensure correct fitment to prevent leaks. Use quality components for better performance. Regular checks help maintain engine health.

Repairing Damaged Valves

Damaged valves lead to compression loss. Inspect valves for cracks or warping. Replace faulty valves immediately. Proper seating ensures no air leaks. Adjust valve clearance as needed. This improves engine efficiency significantly.

Addressing Cylinder Head Issues

Cylinder head problems affect compression. Check for cracks or gasket leaks. Resurface the head if necessary. Ensure proper torque during installation. This prevents future leaks and maintains compression. Regular maintenance keeps the engine running smoothly.

Credit: carfromjapan.com

Preventative Maintenance

Preventative maintenance is crucial for engine health. It helps prevent compression issues in cylinders. By taking proactive steps, you avoid costly repairs. Regular care keeps your engine running smoothly. It extends the lifespan of your vehicle. Below are key areas to focus on.

Regular Engine Inspections

Regular inspections catch problems early. Check for wear and tear routinely. Inspect seals and gaskets for leaks. Look at the spark plugs and wires. A mechanic can spot issues before they worsen. Schedule inspections at least twice a year.

Maintaining Proper Oil Levels

Oil lubricates engine parts. It reduces friction and wear. Low oil levels lead to overheating. Overheating damages cylinder compression. Check oil levels every month. Use the recommended oil type for your engine.

Using Quality Fuel And Additives

Fuel quality affects engine performance. Poor fuel can lead to deposits in cylinders. These deposits hinder compression. Use high-quality fuel for better combustion. Additives clean and protect the engine. They improve compression and efficiency.

Professional Help Vs. Diy Solutions

Having issues with cylinder compression can be a real headache. You might be torn between calling a professional mechanic or rolling up your sleeves to tackle the problem yourself. Each option has its merits, and understanding them can save you time, money, and frustration. Whether you’re a seasoned DIY enthusiast or someone who prefers to leave it to the experts, this guide will help you weigh your options effectively.

When To Consult A Mechanic

Sometimes, the problem can be more complex than it appears. If you’re hearing strange noises from the engine or if the car refuses to start, it might be time to consult a mechanic. They have the expertise to diagnose issues that aren’t immediately obvious.

In my experience, attempting a repair without proper knowledge can lead to bigger expenses. If you’re unsure about the severity of the problem, a professional can provide a clear assessment.

Tools Required For Diy Repairs

If you decide to tackle the issue yourself, having the right tools is crucial. Basic tools include a compression tester, socket set, and torque wrench. These tools help you measure and adjust cylinder compression accurately.

Don’t overlook the importance of a good repair manual. It provides step-by-step instructions tailored to your vehicle’s model. A friend of mine once fixed his compression issue using just a compression tester and a manual, saving hundreds of dollars in the process.

Pros And Cons Of Diy Fixes

DIY repairs can be rewarding and cost-effective. You gain firsthand experience and a sense of accomplishment. However, the learning curve can be steep, especially if you’re unfamiliar with car mechanics.

Consider the time commitment. A DIY fix might take longer than anticipated, and there’s always a risk of making the problem worse. Weigh these factors carefully before deciding.

On the flip side, DIY solutions can be a great way to learn new skills. Plus, you can customize the repair to fit your specific needs. What’s your comfort level with car repairs? Knowing this can guide your decision.

Ultimately, whether you go the professional route or DIY, the key is to ensure your vehicle is in safe working condition. Choose the path that aligns best with your skills and comfort level.

Credit: www.youtube.com

Common Mistakes To Avoid

Improper tightening of spark plugs can lead to compression loss in cylinders. Using low-quality fuel might cause similar issues. Regular maintenance and proper diagnosis are essential to prevent these common mistakes, ensuring your engine runs smoothly and efficiently.

When fixing compression in engine cylinders, avoiding common mistakes can save you time and money. Many people overlook these crucial aspects, leading to bigger issues down the road. Let’s focus on some of these pitfalls and how you can steer clear of them. ###Ignoring Early Warning Signs

Ignoring early warning signs can lead to severe engine damage. You might notice your car’s performance dropping or hear unusual noises from the engine. Acting promptly when these signs appear can prevent costly repairs. A friend of mine once ignored these early symptoms, thinking it was just a minor glitch. It resulted in a complete engine overhaul that could have been avoided with early intervention. ###Using Incorrect Tools

Using incorrect tools can complicate a simple repair job. Ensure you have the right set of tools for engine repair to avoid damaging components. Once, I used a mismatched wrench on a cylinder head bolt, and it stripped the bolt, turning a straightforward task into a nightmare. Double-checking your toolkit before starting work can save you from similar headaches. ###Overlooking Regular Maintenance

Overlooking regular maintenance is like inviting trouble. Regular check-ups can catch issues before they escalate. Skipping scheduled maintenance can lead to unexpected breakdowns. Imagine planning a road trip only to be stopped by a sudden engine failure due to neglected maintenance. Set reminders for routine checks and keep your vehicle in top shape. What common mistake do you find yourself making? Addressing these pitfalls can significantly improve your vehicle’s performance and longevity. Taking small steps can make a big difference.Frequently Asked Questions

How To Fix Compression In A Cylinder?

Fix cylinder compression by checking and replacing faulty parts like piston rings, gaskets, or valves. Inspect for leaks and clean carbon deposits. Ensure proper torque on bolts and use quality parts for repair. Regular maintenance prevents future issues and improves engine performance.

Can Changing Oil Improve Compression?

Changing oil can indirectly improve compression by ensuring engine parts are well-lubricated and reducing wear. Fresh oil helps maintain optimal sealing between piston rings and cylinder walls, potentially enhancing compression. Regular oil changes are crucial for engine health, not a direct fix for compression issues.

What Additive Is Used To Fix Low Compression?

Engine Restore with CSL is often used to fix low compression. It seals leaks and restores cylinder pressure.

What Causes Too Much Compression In A Cylinder?

Too much compression in a cylinder is often caused by carbon deposits, incorrect valve timing, or a damaged head gasket. These issues lead to reduced engine efficiency and performance. Regular maintenance and inspections can help prevent excessive compression problems in your engine.

Conclusion

Fixing cylinder compression requires careful attention and the right tools. Identify the problem first. Check for worn or damaged parts. Replace faulty components promptly. Ensure proper installation during repairs. Regular maintenance can prevent future issues. Use quality parts for long-lasting results.

Keep your engine running smoothly and efficiently. Remember, a well-maintained engine saves time and money. Practice safety measures while working on your vehicle. Consult a professional if you’re unsure. A little effort goes a long way in extending engine life.

Keep learning and stay informed about engine care. Happy driving!