Unlocking the secrets of your engine’s performance can feel like deciphering a complex puzzle. However, understanding one crucial aspect—finding the Top Dead Center (TDC)—can make a world of difference.

If you’ve ever been baffled by engine timing or curious about optimizing your vehicle’s efficiency, you’re in the right place. This guide is crafted just for you, unraveling the mystery of TDC in simple, easy-to-follow steps. Imagine the satisfaction of knowing exactly how your engine ticks and having the confidence to make precise adjustments.

Ready to take control and enhance your engine’s potential? Let’s dive in and discover how you can find TDC on an engine with ease.

Credit: www.wikihow.com

Tdc Basics

Understanding TDC is essential for engine enthusiasts and mechanics. It is crucial for engine timing and performance. Let’s dive into the basics of TDC.

Definition Of Tdc

Top Dead Center, or TDC, refers to a piston’s highest point. It is the point where the piston is at the top of its stroke. This occurs during the compression or exhaust stroke. TDC is a key reference point in engine mechanics. It helps in setting the ignition and valve timing accurately.

Importance In Engine Timing

Precise engine timing ensures smooth and efficient operation. TDC plays a vital role in this process. It helps determine the correct position for spark plug firing. Proper timing reduces engine knocks and improves fuel efficiency. Accurate TDC also aids in valve timing adjustments. This ensures optimal airflow in and out of cylinders.

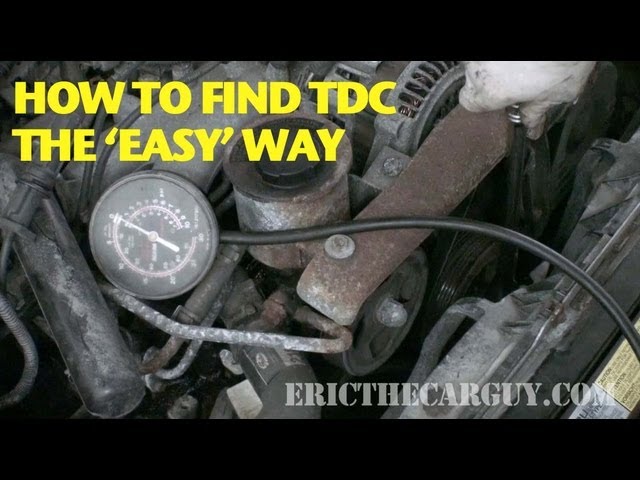

Credit: www.youtube.com

Tools Required

Locating TDC on an engine requires specific tools such as a timing light, socket set, and crankshaft pulley wrench. These tools help ensure precision and ease during the process. Proper equipment aids in accurate alignment and smooth operation.

Finding the Top Dead Center (TDC) on an engine is crucial for tasks such as timing adjustments or engine diagnostics. Having the right tools at your disposal can make this process smooth and efficient. Let’s dive into the essential tools that can help you find TDC with precision. ###Tdc Indicator

A TDC Indicator is a handy tool that shows when the piston reaches the top of its travel in the cylinder. This tool, often a dial gauge, is placed through the spark plug hole. In my own garage, I’ve found that using a TDC Indicator not only saves time but also reduces guesswork. You can visually confirm the exact point of TDC, ensuring accuracy every time. Have you ever thought about how much easier tasks could be with a reliable indicator at hand? ###Piston Stop Tool

The Piston Stop Tool is another essential item in your toolkit. This tool physically blocks the piston from moving past a certain point, helping you determine TDC by gently rocking the crankshaft back and forth. During one of my engine repair sessions, I realized how invaluable this tool was. It provided a solid reference point, eliminating any ambiguity. If precision matters to you, this tool is a must-have. Are you ready to add this to your toolbox? ###Crankshaft Wrench

Using a Crankshaft Wrench is necessary for manually rotating the engine to find TDC. This tool gives you the control needed to turn the engine over slowly and safely. I remember the first time I used a Crankshaft Wrench; it was a game-changer. The ease of rotation and the ability to stop at exactly the right spot made the process stress-free. Have you considered how a simple wrench can enhance your engine maintenance routine? Having these tools not only makes finding TDC more straightforward but also boosts your confidence in handling engine tasks. Which of these tools do you think will transform your DIY projects?Preparation Steps

Finding top dead center (TDC) on an engine requires several preparation steps. First, gather essential tools like a socket wrench and TDC indicator. Next, ensure the engine is off and safe to work on.

Finding Top Dead Center (TDC) on an engine is crucial for tasks like setting the timing or adjusting the valves. Before diving into the mechanics, it’s essential to prepare adequately. Proper preparation not only ensures accuracy but also keeps you safe. Let’s dive into the preparation steps you need to follow. ###Safety Precautions

Your safety is paramount when working on an engine. Always wear safety goggles and gloves to protect yourself from unexpected hazards. Make sure your workspace is well-ventilated to avoid inhaling fumes. Disconnect the car battery to prevent accidental starts. This simple step can save you from potential injuries. Keep a fire extinguisher handy just in case of emergencies. ###Engine Setup

Start by parking the vehicle on a flat surface and engage the parking brake. If you’re working with a manual transmission, place it in gear. This prevents the vehicle from rolling unexpectedly. Remove any obstructions around the engine to give yourself clear access. It might sound obvious, but a cluttered space can lead to mistakes. If your engine has a cover, remove it to gain better access to the necessary components. Position a jack and secure the vehicle with jack stands if you need to work underneath. Never rely solely on the jack to hold the car up. It’s a simple step that often gets overlooked but is crucial for your safety. Have you ever skipped preparation steps and regretted it later? Taking a few extra minutes now can save hours of frustration later. Plus, it ensures you have everything you need before you start. By following these preparation steps, you’ll set yourself up for success in finding TDC on your engine. Are you ready to get started?

Credit: www.youtube.com

Manual Method

Finding the top dead center (TDC) on an engine manually involves rotating the crankshaft. Use a wrench to turn it slowly until the piston reaches its highest point. Ensure the timing mark on the pulley aligns with zero on the timing scale for accurate results.

Finding Top Dead Center (TDC) on an engine using the manual method can be a rewarding experience, especially if you enjoy the hands-on approach to car maintenance. This method doesn’t require fancy gadgets or tools, just a bit of patience and attention to detail. You might be wondering why TDC is so important. It’s crucial for tasks like timing adjustments or verifying engine position. Let’s dive into the steps you need to follow to find TDC manually.Removing Spark Plugs

Start by removing the spark plugs from your engine. This step is essential because it reduces the compression in the cylinders, making it easier to rotate the crankshaft. Use a spark plug socket and a ratchet for this task. As you unscrew each spark plug, take a moment to inspect them. Are they clean or fouled? This could tell you a lot about the health of your engine.Rotating The Crankshaft

Next, rotate the crankshaft using a wrench on the crankshaft pulley bolt. It’s crucial to turn it in the correct direction to avoid damaging your engine. You should feel a bit of resistance, but it shouldn’t be overly difficult. As you turn it, listen to the engine. Does it make any unusual noises?Locating Tdc

To locate TDC, you’ll need to watch for the piston to reach its highest point in the cylinder. Use a flashlight to look inside the spark plug hole, or insert a small screwdriver and feel for the piston. It’s amazing how simple tools can help you understand complex mechanisms. Once you find TDC, mark it on the crankshaft or the pulley. This will save you time the next time you need to find it. Finding TDC manually is not just about following steps; it’s about getting to know your engine. How did you feel the first time you successfully found TDC? Did it boost your confidence in handling car maintenance? Share your thoughts or experiences. Your insights might inspire someone else to try the manual method.Using A Tdc Indicator

Finding the top dead center (TDC) on an engine is crucial for various maintenance tasks. Using a TDC indicator simplifies this process, ensuring precision. Whether you’re a seasoned mechanic or a car enthusiast, mastering this technique can boost your engine’s performance. So, how can you use a TDC indicator effectively?

Installing The Indicator

First, ensure your engine is off and cool. Safety is your priority. Locate the spark plug hole of the cylinder you are testing.

Remove the spark plug and carefully insert the TDC indicator. It’s like threading a needle; precision matters. Secure it tightly to prevent any movement.

Remember the first time I tried this? I was hesitant, but once the indicator was snug, the process became straightforward. Don’t rush; patience is key.

Reading The Indicator

Turn the crankshaft slowly with a wrench. You’ll notice the indicator’s needle or dial move. This is your moment of truth.

Look for the exact point where the needle stops moving and starts returning. This is your TDC. The magic spot where everything aligns.

How did you feel when you found your first TDC? It’s a small triumph, like solving a puzzle. This indicator makes it tangible and clear.

Imagine having a friend who struggles with engine timing. Could showing them this technique help? TDC indicators simplify the process, providing a visual cue that is easy to understand.

Now, you’re ready to adjust or inspect your engine with confidence. Isn’t it satisfying to know you have pinpointed the exact spot?

Piston Stop Technique

Finding Top Dead Center (TDC) on an engine is simplified using the piston stop technique. Insert a tool through the spark plug hole to block the piston’s movement. Rotate the engine until the piston touches the stop, noting the crankshaft position.

Finding the Top Dead Center (TDC) on an engine is crucial for accurate timing adjustments. One of the most reliable methods to achieve this is the Piston Stop Technique. This technique ensures you pinpoint TDC with precision, offering peace of mind that your engine’s timing is perfectly aligned. It involves using a simple tool—a piston stop—to physically halt the piston’s movement, giving you an accurate reference point.Setting Up The Piston Stop

First, gather your tools. You’ll need a piston stop, a socket wrench, and a breaker bar. A piston stop is a simple tool that you can purchase at any auto parts store. Start by removing the spark plug from the cylinder you’re working on. This gives you access to the piston without any compression resistance. Next, rotate the engine using a socket wrench until the piston is near the top of the cylinder. Carefully insert the piston stop into the spark plug hole and tighten it securely. Make sure it’s snug, but avoid over-tightening as this can damage the threads.Finding Tdc With Piston Stop

With the piston stop in place, rotate the engine clockwise using a breaker bar. You’ll feel the piston come to a stop as it contacts the tool. Mark this position on the crankshaft pulley with a marker or chalk. Now, rotate the engine counter-clockwise until the piston again hits the stop. Mark this second position on the crankshaft. The true TDC is the midpoint between your two marks. Measure the distance between the marks and find the center. This is your TDC. Ask yourself: How much more confidence would you have working on your engine knowing it’s timed perfectly? This method is not just accurate but also builds your understanding of your engine’s internal workings. It’s a rewarding process that can save you headaches in the long run. Plus, you’ll have a newfound appreciation for the mechanics behind your ride. Have you tried the piston stop technique before? If not, give it a go and see the difference it makes in your engine’s performance.Verifying Tdc

Locating the top dead center (TDC) on an engine is crucial for accurate timing and maintenance. Start by removing the spark plug and inserting a screwdriver to feel the piston. Rotate the crankshaft until the piston reaches its highest point.

This ensures optimal engine performance and efficiency.

Finding Top Dead Center (TDC) on an engine is a crucial step for many mechanical tasks, from setting the timing to checking the health of your engine’s internals. But finding TDC is only half the battle. Verifying it ensures accuracy and avoids any mishaps down the road. Let’s dive into how you can confidently verify TDC with some practical techniques.Double-checking Alignment

Ensuring your engine is truly at TDC requires careful observation. One method is to use a piston stop tool. Insert it into the spark plug hole, then gently rotate the crankshaft until the piston comes to a halt. Mark this point on the pulley, then rotate the crankshaft in the opposite direction until it stops again. Mark this second point. The true TDC is precisely between these two marks. Another approach is to observe the valves. At TDC on the compression stroke, both the intake and exhaust valves should be fully closed. This can be confirmed by manually checking the rocker arms. If there’s any movement, adjust accordingly until both are stationary.Using Timing Marks

Timing marks are your engine’s built-in guide. Most engines have a mark on the crankshaft pulley and a corresponding pointer on the engine block. These marks align perfectly at TDC. However, over time, these marks might become less visible due to grime or corrosion. Cleaning them can often reveal the precise alignment. If your engine’s marks are faint or absent, a timing light can be a savior. Attach it to the number one spark plug wire, and observe the strobe light as the engine runs. The light will flash on the timing marks, allowing you to verify their alignment without stopping the engine. Timing marks can shift if the timing chain or belt is worn. Regularly checking these marks can save you from bigger problems. Have you ever relied on timing marks, only to find out they were slightly off due to wear? It’s a small detail, but it can have a big impact. Verification is not just about finding TDC; it’s about ensuring precision in every step. When you question and double-check your methods, you lay the groundwork for successful engine maintenance. Are you ready to make your engine hum with perfect timing?Common Mistakes

Finding the Top Dead Center (TDC) on an engine can be tricky. Many make mistakes that lead to inaccurate readings. Understanding these mistakes can save time and effort. Let’s delve into some frequent errors.

Misreading The Indicator

Misreading the indicator is a common error. The indicator may seem precise, but small misalignments can occur. Always double-check the readings to ensure accuracy. Mark the pulley clearly to avoid any confusion. Misinterpretations can lead to incorrect engine timing.

Incorrect Piston Stop Use

Incorrect piston stop use can cause errors in finding TDC. Using the wrong type of piston stop can damage the engine. Ensure you have the right tool for your engine model. Insert the piston stop gently to avoid causing harm. A rough insertion can lead to inaccurate measurements.

Advanced Tips

Discovering top dead center (TDC) on an engine involves aligning the piston at its highest point in the cylinder. Using a timing light and crankshaft markings aids accuracy during this process. Ensure tools like a dial indicator provide precise measurements for optimal engine performance.

Finding Top Dead Center (TDC) on an engine is a critical step for many mechanical tasks. But there’s more to it than just turning a crankshaft and aligning marks. Advanced tips can help you achieve precision and efficiency. Whether you’re a seasoned mechanic or a curious hobbyist, these insights can elevate your skills. It’s not just about getting the job done; it’s about doing it with finesse.Using Technology Aids

Technology can be your best friend in locating TDC. Digital tools, like electronic gauges, offer precision that traditional methods may lack. These devices display real-time data, allowing you to pinpoint TDC with unmatched accuracy. Imagine using a smartphone app that connects to your engine via Bluetooth. It could display live readings, making adjustments a breeze. It’s like having a personal mechanic in your pocket, guiding you step-by-step. Consider investing in a digital dial indicator. These tools provide instant feedback, eliminating guesswork and saving time. Have you ever thought a small tech upgrade could make such a big difference?Professional Techniques

Relying on professional techniques can make a world of difference. The experienced touch brings a depth of knowledge that gadgets can’t replace. Have you tried using a piston stop tool? It’s a simple yet effective way to find TDC without fancy equipment. Another technique involves using a degree wheel. Attaching it to the crankshaft can help measure precise angles. It’s a method trusted by professionals for years, proving that sometimes, the classics are unbeatable. Always double-check your readings. A second look can ensure accuracy and prevent costly mistakes. What if taking a few extra minutes could save hours of troubleshooting later? These advanced tips are not just for experts; they’re for anyone eager to improve their engine work. Why settle for average when excellence is within reach? Equip yourself with these insights and watch your skills grow.Frequently Asked Questions

How To Find Tdc On Engine?

To find TDC on an engine, remove the spark plug. Insert a dial indicator into the cylinder. Rotate the crankshaft until the piston reaches its highest point. Verify using timing marks on the crankshaft pulley. Ensure accuracy by checking the service manual for specific instructions.

How To Find Tdc Without Tool?

To find TDC without a tool, remove the spark plug and insert a straw. Turn the crankshaft slowly until the straw reaches its highest point. This indicates Top Dead Center.

Is Tdc Always Cylinder 1?

TDC, or Top Dead Center, refers to the highest position of a cylinder’s piston. It isn’t exclusive to cylinder 1. Each cylinder reaches TDC during its cycle, but cylinder 1 is often referenced for timing adjustments. Always check the specific engine manual for accurate identification.

How Do I Know If My Piston Is At Tdc?

Check the timing mark on the crankshaft pulley aligns with the zero mark on the timing scale. Insert a probe into the spark plug hole to feel the piston at its highest point. Use a TDC tool for precise measurement.

Conclusion

Finding TDC on an engine is not as hard as it seems. Follow the steps carefully, and you’ll succeed. Remember, practice makes perfect. Tools like a timing light can help. They make the process easier and faster. Always ensure safety first before starting.

Keep your workspace organized. This helps prevent mistakes. Understanding TDC can enhance your engine maintenance skills. It can lead to better engine performance. Knowing your engine inside and out is valuable. With patience and focus, you can master this important task.